Windstory #17 - A new life for decommissioned blades

What can we do with decommissioned wind turbine blades? The possibilities are varied, and some, quite surprising.

Hello everyone and welcome to a new issue of Windletter. I'm Sergio Fernández Munguía (@Sergio_FerMun) and here we discuss the latest news in the wind power sector from a different perspective. If you're not subscribed to the newsletter, you can do so here.

Windletter is sponsored by:

🔹 Tetrace. Reference provider of O&M services, engineering, supervision, and spare parts in the renewable energy market. More information here.

🔹 RenerCycle. Development and commercialization of specialized circular economy solutions and services for renewable energies. More information here.

🔹 Nabrawind. Design, development, manufacturing, and commercialization of advanced wind technologies. More information here.

Windletter está disponible en español aquí

Windstory is the articles section of Windletter, where we publish single-topic analyses and share interesting stories from the wind energy sector.

From time to time, without a set schedule, a new edition of Windstory will arrive in your inbox.

Before starting, a kind reminder. As some of you may already know, the Spanish media El Periódico de la Energía has nominated me for the “Best Energy Communicator” award, which will be presented during their annual event: La Noche de la Energía.

The competition is really tough, but I’d love to count on your vote to see if I can make it to the finalists and bring the name of Windletter to the top 🙂

It only takes about 30 seconds to vote and the process is as follows: you just need to enter your email address in the form you’ll find at this link. Then, you’ll receive an email with a link where you can cast your vote.

Thanks a lot in advance to everyone!

♻️ A second life for decommissioned wind turbine blades

The european wind turbine fleet is getting old. More than 26 GW of wind power in Europe have already exceeded 20 years of operation, and another 57 GW will do so before the end of the decade.

The design lifetime of a wind turbine is usually between 20 and 25 years, although the reality of the sector shows that many assets remain in operation beyond that threshold.

Thanks to the robustness of the designs, improvements in maintenance and/or specific retrofits, lifetime extension up to 30 or 35 years has become a relatively common practice. Furthermore, in many countries, full repowering is limited by administrative or economic barriers, which pushes owners to prioritize lifetime extension.

On average, Denmark, Spain and Portugal have the oldest wind turbines. Additionally, Germany and Spain have the greatest repowering potential in the coming years, with 21 GW and 19 GW of assets over 15 years old, respectively.

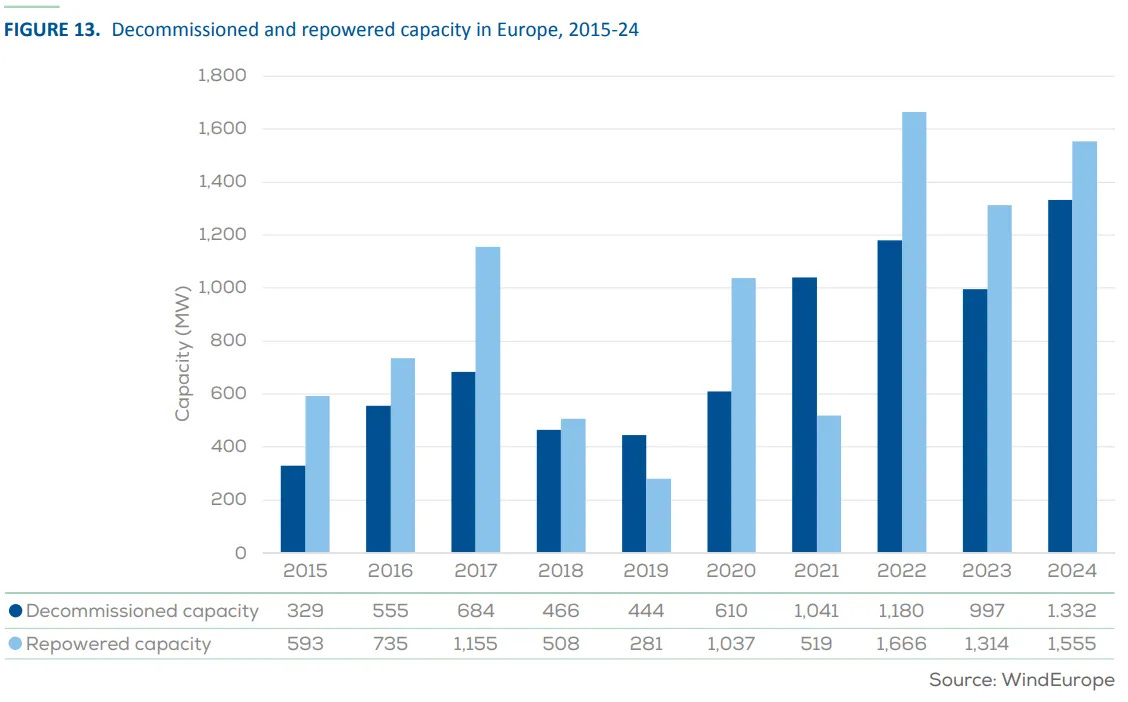

Since 2015, 7,638 MW have been decommissioned in Europe, with 1,332 MW dismantled in 2024. Germany (712 MW) and Spain (435 MW) have been the countries with the highest activity, according to data from Wind Europe.

So, in the next 10–15 years, the aging of the European wind fleet represents a major challenge. Not only from a technical or economic standpoint, but also from an environmental perspective. In a few years, we will be facing hundreds of decommissioned wind turbines, whose components will need to be properly managed.

How do we recycle their components? What circular solutions can we apply? How do we ensure that this growing volume of equipment does not become an environmental liability?

Before recycling, reuse

In general terms, most components of a wind turbine are recyclable. Currently, around 85–90% of the materials in a wind turbine can be recycled.

Turbines are mainly manufactured from just six basic raw materials: steel, cast iron, fiberglass (and similar composite materials), copper, aluminum, and the concrete used in the foundations.

While most of these materials already have an established and industrialized recycling chain, the challenge for the wind sector lies in recycling the blades, which are made of composite materials (primarily fiberglass, carbon fiber, and resins), particularly difficult to separate for proper recycling.

There are already companies doing very interesting work in blade recycling, such as our sponsor RenerCycle, but we will leave that for another edition.

But before recycling, a logical step is reuse. Taking advantage of the blade structure to find new functionalities.

What can we do with decommissioned wind turbine blades? That is the question many startups and universities around the world are beginning to ask themselves. And the truth is that the possibilities are very diverse. Certainly, none seem likely to become mass-market solutions, but it is undeniable that very interesting and curious applications are emerging.

🎠 Children's playgrounds

In Rotterdam, the Netherlands, we find one of the first examples of creative reuse of wind turbine blades: the Wikado playground, designed by Superuse Studios, manufactured by Blade-Made, and built as early as 2009.

As can be seen, several blades were cut and transformed into structures such as tunnels, towers, slides, and bridges that today form part of the urban furniture for children's play.

After the success of the Rotterdam playground, other nearby towns have followed the example, building similar spaces.

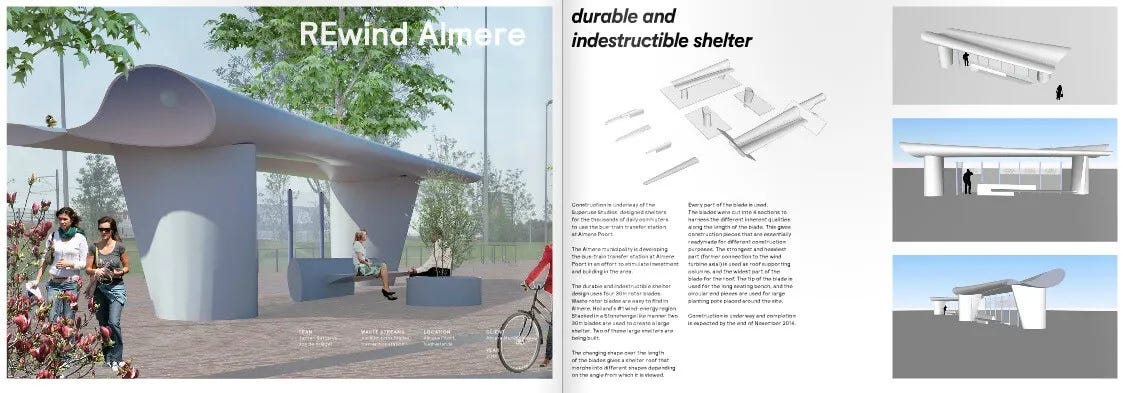

🏠 Canopies or shelters

One of the applications with the greatest potential for the reuse of wind turbine blades is their use as canopies. Thanks to their curved shape, a simple cut is enough to turn them into fully functional shelters.

A good example can be found in the port of Aalborg (Denmark), where a blade segment has been transformed into a covered bicycle parking area.

The company RE-Wind has also developed a canopy specifically designed to function as a bus stop, although in this case composed of several pieces.

🪑 Street furniture

Also in Rotterdam, specifically in Willemsplein square, several blades have found a new purpose as urban furniture. In this case, they have been reused to create public seating that gives shape and character to this central space.

Unlike other projects, since they come from small wind turbines, in this case the blades have not been cut or structurally modified, only painted red (although in Maps they now appear painted in various colors).

Not all examples of reuse have to be monumental. From the company ANMET we receive proposals of urban furniture less ambitious in size, but just as striking in design.

From fragments of wind turbine blades, ANMET has developed benches, planters, tables, and decorative elements that combine functionality with aesthetics.

🌉 Bridges

Among all possible second lives, the construction of bridges with wind turbine blades stands out for its spectacular nature… and its complexity.

In these cases, the blade is not just a decorative element, but a structural part of the bridge, which involves a more demanding engineering effort. the solution has been designed and manufactured by bladebridge, which also has other interesting products in its catalog. they even have a unit installed in ireland, as you can see in the photo above.

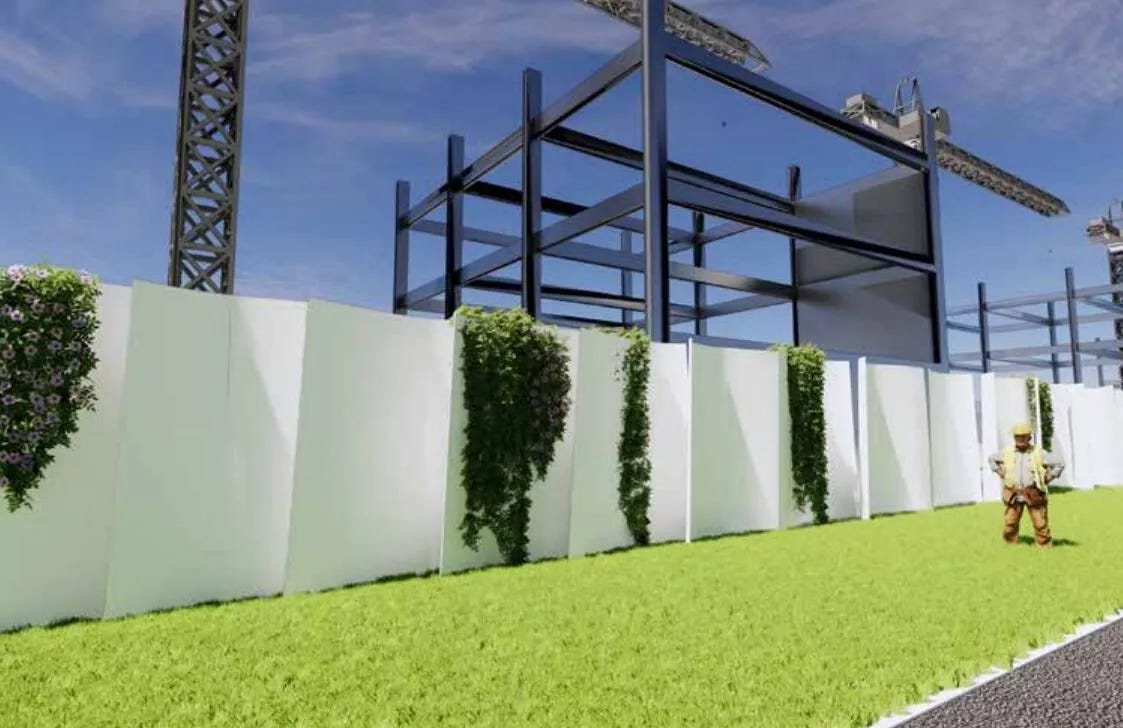

🔇 Acoustic barriers

Among the most ingenious applications in the RE-wind catalog is the use of chopped blades as acoustic barriers. an innovative solution for one of the most common elements of road furniture: the walls that separate roads from urban or pedestrian areas.

Moreover, since the blades are hollow, they can be filled with soil and turned into supports for integrated vegetation, creating green walls with acoustic insulation.

⚡ Electrical towers for overhead lines

One of the most innovative and curious uses currently being explored for decommissioned wind turbine blades is their reuse as electrical towers for power transmission.

This idea, which maintains a functional link with energy generation and distribution, has been investigated by a team from the Georgia Institute of Technology (Georgia Tech), in Atlanta. As a proof of concept, the engineers have built a first prototype measuring 6 meters in height.

However, its large-scale application raises reasonable doubts. Electrical towers are critical components of the grid, subject to high demands in terms of safety, durability, and technical regulations. They are expected to have a very long service life, and in most countries their design and specifications are regulated by very strict standards established by transmission system operators (TSOs) or distribution companies.

🏡 Bungalows

This collaboration between Vattenfall, the design studio Superuse, and Blade-Made transformed the nacelle of a Vestas V80 2 MW into a beautiful module ready to move into.

Its dimensions are 4 meters wide, 10 meters long, and 3 meters high, resulting in a kind of bungalow of about 40 square meters that is quite charming.

Some said they’d rather wait for the V236 to be adapted 😂

Thank you very much for reading Windletter and many thanks to Tetrace, RenerCycle and Nabrawind our main sponsors, for making it possible. If you liked it:

Give it a ❤️

Share it on WhatsApp with this link

And if you feel like it, recommend Windletter to help me grow 🚀

See you next time!

Disclaimer: The opinions presented in Windletter are mine and do not necessarily reflect the views of my employer.