Windstory #14 - 7 wind turbines of 100 kW for an island of 400 inhabitants in the Azores (II)

The history and technology behind the Corvo Island wind farm, a project by Norvento Enerxía located on a small island in the Azores and equipped with 7 wind turbines of 100 kW each.

Hello everyone and welcome to a new issue of Windletter. I'm Sergio Fernández Munguía (@Sergio_FerMun) and here we discuss the latest news in the wind power sector from a different perspective. If you're not subscribed to the newsletter, you can do so here.

Windletter is sponsored by:

🔹 Tetrace. Reference provider of O&M services, engineering, supervision, and spare parts in the renewable energy market. More information here.

🔹 RenerCycle. Development and commercialization of specialized circular economy solutions and services for renewable energies. More information here.

🔹 Nabrawind. Design, development, manufacturing, and commercialization of advanced wind technologies. More information here.

Windletter está disponible en español aquí

Windstory is the articles section of Windletter, where we publish single-topic analyses and share interesting stories from the wind energy sector.

From time to time, without a set schedule, a new edition of Windstory will arrive in your inbox.

Let’s move on to the second part of the story of the Corvo Island wind farm. To enjoy the full experience, read the first part here.

100 kW wind turbines and an island of 400 inhabitants in the Azores

Loading, transport and installation

Through its YouTube channel, Norvento Enerxía has shared many details about the project, ranging from the loading of the wind turbines at the factory to their transport and installation.

Note: The video below was originally in Spanish and has been translated into English by Windletter using an AI tool.

Thanks to the videos we can see many details. Regarding transport, we highlight:

It is carried out in standardized shipping containers, complying with the required dimensions at the destination port and optimizing logistics costs, which are always lower when standard dimensions are used.

A single container can transport the nacelle, the three blades, and other additional components such as the electronic converter.

In another separate container, the tower is transported, with segments designed to allow telescopic storage (that is, one tower section inside another, in a "matryoshka" style). This tower concept was already seen with the Vestas V52 at Lake Turkana.

Norvento had to bring a crane and a truck exclusively to the island in order to unload, transport, and assemble the components.

Note: The video below was originally in Spanish and has been translated into English by Windletter using an AI tool..

Regarding the assembly, we highlight:

It is not very different from the conventional installation of a wind turbine, with the main difference being that the components are at a much smaller scale.

The workers have very little space inside the tower to wait for the next tower section or for the nacelle.

The rotor installation is particularly noteworthy, as the technician has to wait seated on top of the nacelle, whereas in large-scale wind turbines, operators usually wait inside the nacelle.

It was probably also a significant challenge to wait for appropriate wind windows given the wind resource present on the island.

Technical data of the nED100

According to the IEC 61400-2 standard, a small wind turbine (or small-scale wind turbine) is defined as one whose rotor swept area is less than 200 m². According to APPA, the Spanish Renewable Energy Producers Association, small wind power is defined as the use of wind resources through wind turbines with a power output below 100 kW.

Taking these definitions into account, the nED100 sits on the threshold of being officially considered small wind, although personally I believe that boundary is very blurry.

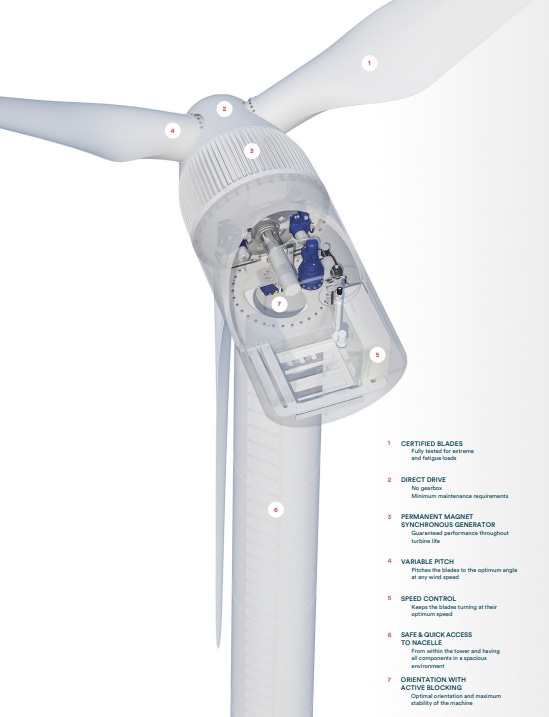

In any case, and despite being a 100 kW wind turbine, the nED100 features technologies similar to those of multi-megawatt wind turbines, in addition to being manufactured and tested according to international industry standards.

You can access the catalogue with all technical data here.

Of course, in addition to the standard technical specifications, each project includes its own specific requirements. In the case of Corvo Island:

There is a small prefabricated cabin next to each wind turbine housing a transformer to step up the output voltage from 400 V to 15 kV.

The machines have a CX surface finish due to the corrosive marine environment.

Installation of a SCADA system that allows monitoring and control of all components in the wind farm and is compatible with the system developed by EDA Renováveis.

Norvento has a fleet of around 40 wind turbines of this model installed across various locations in the United Kingdom, Spain, and Portugal. A map with the locations can be viewed here, highlighting their strong presence in the United Kingdom.

Origins and manufacturing of the nED100 wind turbine

Norvento came up with the idea of manufacturing a 100 kW wind turbine in 2008, during the full expansion of distributed generation. It was then that the Galician company believed that wind energy should have its own space in this growing sector.

At that time, there was no wind turbine on the market for this application and within this power range. With the design of the nED100 wind turbines, Norvento aimed to fill this niche.

Norvento designs and manufactures the nED100 wind turbine at its factory in Vilalba (Lugo). The company follows a mixed philosophy for component sourcing:

Some components are Norvento’s own designs (the tower and the structural elements of the nacelle).

Others are purchased based on technical specifications.

Some are commercial components.

All materials are assembled at the factory, where exhaustive testing is also carried out to ensure the equipment complies with the relevant quality and safety standards.

The wind turbine has undergone design updates over time. This is what it looked like in its first generation.

Conclusions

The truth is that it is undeniable that the nED100 is a special, different product — but also a niche product. Small-scale wind power is still an emerging sector and has yet to gain real traction due to the complexities it faces.

The cost reduction and simplicity of photovoltaic solar technology put small wind at a disadvantage, as it requires more preliminary studies (for example, measuring the wind resource) and also faces greater challenges during operation (maintenance, noise).

However, the reality is that there are places in the world which, due to their special conditions (such as the island of Corvo), are a perfect location for this type of product. Another example would be bases in Antarctica, where small-scale wind is a great option. In fact, there is a small 1 MW wind farm with 3 Enercon E-30 turbines powering some settlements there.

Industrial parks, ports, remote farms and isolated communities are other niches where Norvento sees potential.

Without a doubt, the Corvo Island project is a special one, with a unique technology. A story that deserves to be told. We will closely follow Norvento’s next steps and its nED100.

Thank you very much for reading Windletter and many thanks to Tetrace, RenerCycle and Nabrawind our main sponsors, for making it possible. If you liked it:

Give it a ❤️

Share it on WhatsApp with this link

And if you feel like it, recommend Windletter to help me grow 🚀

See you next time!

Disclaimer: The opinions presented in Windletter are mine and do not necessarily reflect the views of my employer.

I wonder how they will maintain these turbines. Will technicians come from Spain?