Windletter #88 - OceanX, the dual-rotor floating platform by Mingyang, installed at its final location

Also: Nordex installs the prototype of the N175/6.X, Mingyang aims to enter Italy, not all wind resources are equal, and more.

Hello everyone and welcome to a new issue of Windletter. I'm Sergio Fernández Munguía (@Sergio_FerMun) and here we discuss the latest news in the wind power sector from a different perspective. If you enjoy the newsletter and are not subscribed, you can do so here.

Windletter is sponsored by:

🔹 Tetrace. Specialized services in operation and maintenance, engineering, supervision, inspection, technical assistance, and distribution of spare parts in the wind sector. More information here.

🔹 RenerCycle. Development and commercialization of solutions and specialized services in the circular economy for renewable energies, including comprehensive dismantling of wind farms and waste management, refurbishment and sale of components and wind turbines, management and recycling of blades and others. More information here.

Windletter está disponible en español aquí

The most-read from the last edition were: the high-quality video of the Vestas V126 installation, Claus Engholm Nielsen's 40 years at Vestas, and techniques for reducing noise during monopile installation.

Let's dive into this week's news.

🌬️ Mingyang completes OceanX assembly and transports it to its final location

Mingyang has successfully transported its innovative double-rotor floating platform, OceanX, to its final location. The platform, which boasts a total capacity of 16.6 MW (2 x 8.3 MW), was towed to its final site, 700 kilometers away (approximately a 72-hour journey) off the southeast coast of China. It has been installed at the existing Qingzhou IV Offshore Wind Farm.

To celebrate this milestone, a significant amount of content in the form of photos and videos has circulated online, which I've decided to compile here.

Mingyang’s president, Qiying Zhang, has been quite active on LinkedIn lately, sharing posts with brief insights about the prototype, often with very concise captions (more like tweets). He has shared photos of the transportation (1 and 2), videos of the platform at its final location (1 and 2), and images of marine life around the platform.

However, the best quality videos and images can be found on YouTube. The video I’ve linked below shows numerous details of the platform’s assembly, from the concrete segments that make up the floater to the installation of the nacelles and rotors (incidentally, the rotors were assembled as a complete unit). It also includes footage of the launch and part of its transport, with an impressive underwater tunnel as a backdrop.

Mingyang has also released a video with more of a marketing approach, but it’s still quite cool. It has very few views (24 at the time of writing this), so you can feel special if you watch it 😁.

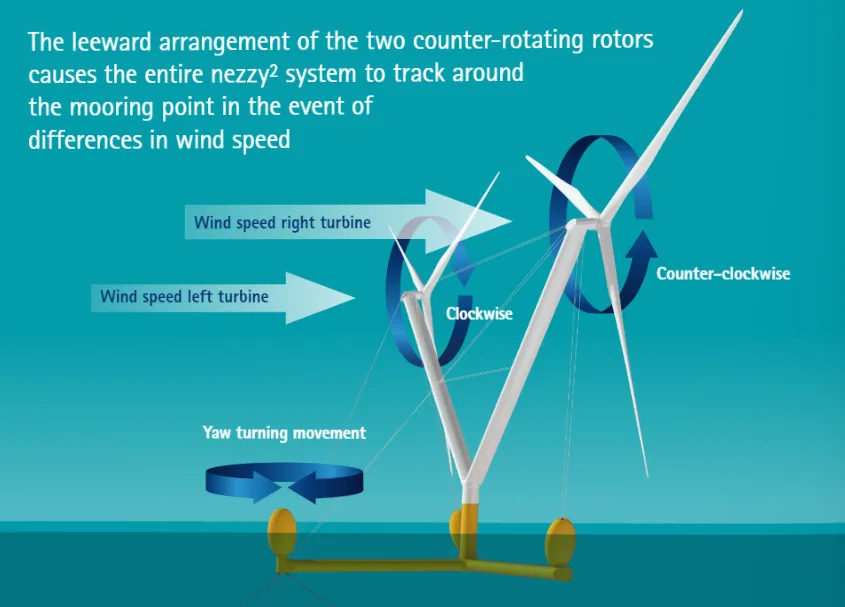

One very important technical detail I overlooked is that OceanX is a platform that operates downwind, meaning that the wind hits the back of the nacelle rather than the side facing the hub.

This allows the entire structure to rotate around its anchoring point, enabling it to passively align with the wind direction, like a vane. As you can imagine, the nacelles don’t have a yaw system. This is the same solution proposed by X1 Wind in their PivotBuoy platform.

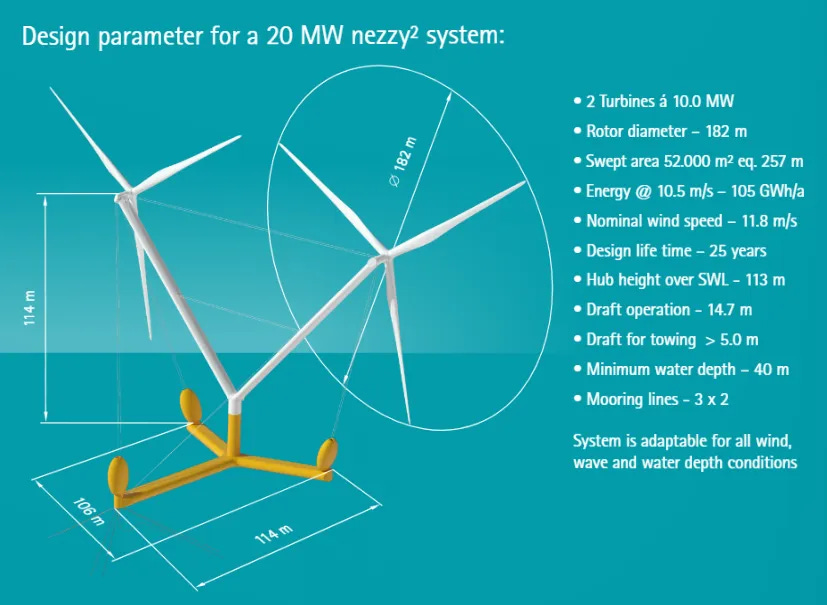

For those more curious, I’m also including a link to the Aerodyn Engineering catalog, the inventors of this concept, which describes many technical aspects of the structure.

The catalog also includes comparisons with other platform types (page 23), LCOE comparisons for different locations (page 27), and even technical data for a hypothetical 20 MW platform (2 x 10 MW). It’s worth taking a look.

Personally, I find this prototype fascinating, and I’m glad someone is willing to invest in such ventures.

The reality is that there’s still a long way to go before this platform can become a commercial reality, but having a full-scale prototype is always a crucial step, and that step has now been taken.

Whatever the outcome, it’s undeniable that this is an exceptional engineering piece.

Before continuing…

As many of you may have been on vacation during the summer months, it's possible you might have missed an issue of Windletter. So, if you’re interested, you can check your inbox to make sure you haven’t missed any editions.

Could you help me continue growing? Share Windletter with someone you think might like it. You can forward this email, share it on social media, or even send the link via WhatsApp by clicking here.

From now on, from time to time I will be recommending products or services here. They will always be products or services that I use myself.

_

🏗️ Nordex installs the N175/6.X prototype

Despite a deceleration in the development of new products by Western manufacturers, the reality is that all of them are working on prototypes for their new onshore models.

Before we went on vacation, we talked about Enercon and Vestas, who are working on the E-175 EP5 E1 and V172-7.2MW™ respectively. Nordex, for its part, has also recently installed the N175/6.X prototype in Germany.

Once again, the German manufacturer has chosen an interesting approach for installing this prototype. Instead of doing it at a testing center (similar to Østerild in Denmark or Alaiz in Spain), it has been done at a community-owned wind farm, suggesting that some agreement was reached with the owners.

This is similar to the N155/5.X prototype installed in Navarra following an agreement with RWE. It's a way to reduce the cost of prototype development, which is not insignificant.

The prototype is installed on a 112 meter tubular steel tower, and next fall, a second prototype of 179 meters will be installed on a hybrid concrete-steel tower.

Siemens Gamesa and GE Vernova are still missing from this race. The former due to issues with the SG5.X-170, which saw sales halted, and it’s still unknown when it will return (or if they will jump directly to the next model). As for GE, their strategy so far has been to minimize their product portfolio, leading them to not announce anything beyond their Cypress 6.0-164 for now.

_

🤝 Mingyang signs an agreement with an Italian developer for 2.8 GW of floating wind

Recently, in edition #85, we discussed how Mingyang was getting closer to entering the European offshore wind sector. Luxcara, a German developer, had chosen the Chinese manufacturer as its preferred supplier for a 296 MW wind farm in German waters.

However, the latest news about Mingyang is even more significant. The manufacturer is in discussions with the Italian developer Renexia to supply 2.8 GW for their floating Med Wind project in Italian waters. This was announced by Renexia itself via LinkedIn.

But the agreement doesn't stop there. The discussions have been formalized into a pre-agreement (MoU) backed by the Italian government, which includes the construction of a Mingyang factory in the country. As I understand it, the factory would be a joint venture between Renexia and Mingyang, with an initial announced investment of 500 million euros.

The plant would be equipped to manufacture the 18.X MW models, and its first order would be the 148 units for the Med Wind project.

This is not the first time Renexia has worked with Mingyang. In fact, the only offshore wind farm in Europe (although it is a sort of nearshore project) with Mingyang wind turbines is the Beleolico project, located in the Taranto area. The farm will consist of 10 MySE 3.0-135 turbines, totaling 30 MW.

_

🏭 Haizea Wind launches facilities with the manufacturing of the first monopile for East Anglia Three

The tower and monopile manufacturer Haizea Wind has announced the production of the first unit of the 50 monopiles it will deliver to Scottish Power (Iberdrola's subsidiary in the UK) for the East Anglia Three wind farm.

The monopile has left Haizea Wind’s expanded facilities in the port of Bilbao.

Once completed, East Anglia Three will have an installed capacity of 1,400 MW and will feature 95 Siemens Gamesa turbines with 14.X MW capacity.

The photo below shows the incredible size of these structures.

_

🌬️ Not all wind resources are the same

I really enjoyed this post by Jerry Randall of Wind Pioneers. In it, Jerry elaborates on the idea that not all wind resources are equal.

In the days of feed in tariffs (the famous ‘premiums’ for renewables), all energy injected into the grid was paid at the same price, regardless of whether it was produced on a warm summer afternoon or a cold winter night.

For this reason, the main parameter to look at to see if a location had a good wind resource was simply the average annual velocity. Thus, almost all wind maps that have circulated historically referred to that parameter.

But times have changed. Now there are merchant wind farms (that sell energy to the market), hourly PPAs... and it is no longer only relevant how much energy you generate but when you generate it.

To give an example with an extreme case. If we were to find a location in Spain with a wind resource with an hourly curve that coincides with the hours of solar generation, a priori it would not be a very attractive wind farm at this time. The reason is that its generated energy would have to compete with photovoltaic generation and would capture less revenue in the market.

To understand this better, check out Jerry's post.

_

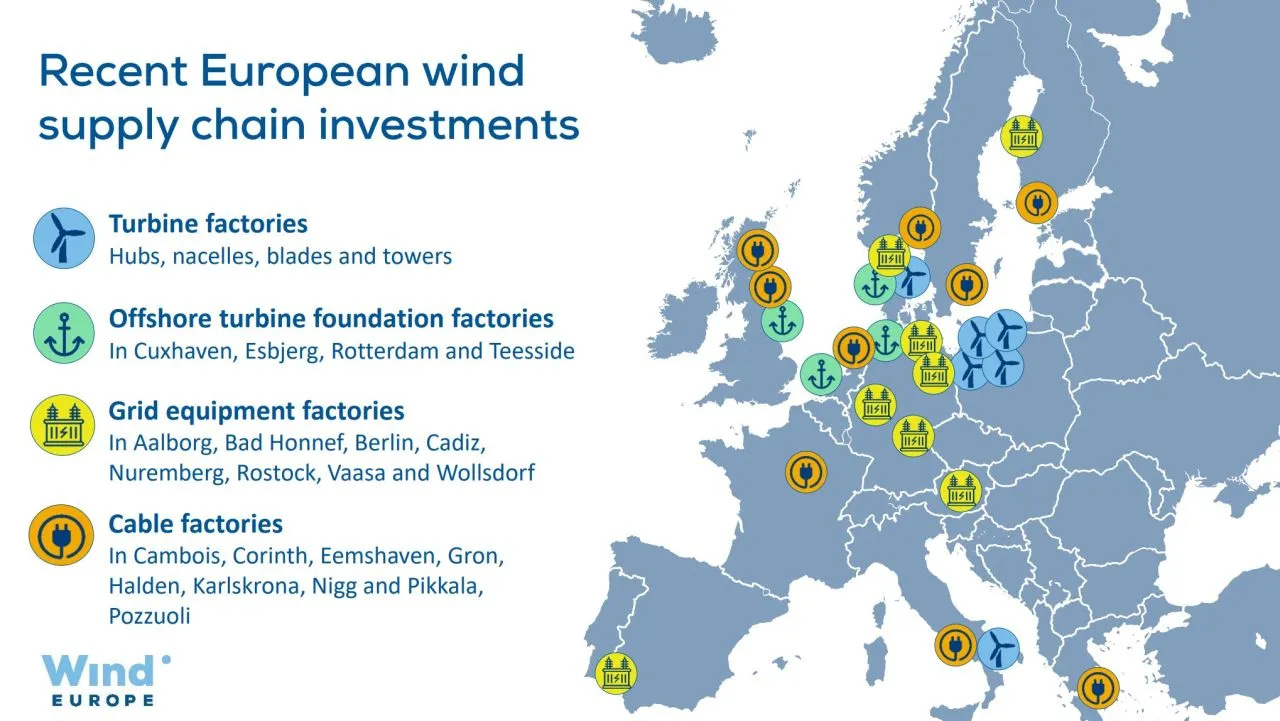

💼 A look at recent investments in the European wind supply chain

Despite a somewhat pessimistic atmosphere (or at least that's my feeling), the reality is that Europe continues to invest in the wind and electrical equipment supply chain.

WindEurope has compiled an infographic detailing all the recent investments in the European supply chain, distinguishing between wind turbine factories, offshore foundation factories, electrical equipment, and cables.

In many of these investments, the EIB (European Investment Bank) has played a significant role, both in the form of guarantees and loans.

_

🔧 Hywind Scotland is back in operation after corrective maintenance

Hywind Scotland, located off the coast of Peterhead (Scotland), is considered the world's first floating offshore wind farm. It consists of 5 SWT6.0-154 turbines.

In January 2023, it celebrated 5 years with an impressive capacity factor of 54%. However, earlier this year, it was announced that the turbines would be towed to port for corrective maintenance.

Now, Global Maritime has announced that Hywind Scotland is back online. According to their update, 2 of the park’s turbines have been re-secured and reconnected, while a third is being transported back to its location.

More details can be found in Global Maritime's post.

As we discussed in edition #67, floating wind may not be as straightforward as it seems.

_

🚁 Ørsted Uses Heavy-Lift Drones to Transport Components to Offshore Wind Farms

The Danish giant Ørsted has for the first time utilized heavy-lift drones for maintenance tasks at the Borssele 1 and 2 offshore wind farms in the Netherlands.

The drones weigh 70 kg, have a wingspan of 2.6 meters, and a payload capacity of 100 kg. In this instance, Ørsted used them to transport emergency and safety equipment for the wind turbines.

Typically, to replace this equipment, a vessel would navigate from turbine to turbine, using hoists to lift the box onto the transition piece first and then to the nacelle. With drones, the time, cost, and CO2 emissions are reduced, while the safety of personnel is increased.

Here’s a video below.

Thank you very much for reading Windletter and many thanks to Tetrace and RenerCycle, our main sponsors, for making it possible. If you liked it:

Give it a ❤️

Share it on WhatsApp with this link

And if you feel like it, recommend Windletter to help me grow 🚀

See you next time!

Disclaimer: The opinions presented in Windletter are mine and do not necessarily reflect the views of my employer.