Windletter #101 - Windcatcher, the floating multi-turbine wind generator, secures funding for a 40 MW prototype

Also: the second-life journey of gearboxes, use of tower cranes in wind farms, unlimited wind farm configurations for wind resource studies, and more.

Hello everyone and welcome to a new issue of Windletter. I'm Sergio Fernández Munguía (@Sergio_FerMun) and here we discuss the latest news in the wind power sector from a different perspective. If you enjoy the newsletter and are not subscribed, you can do so here.

Windletter is sponsored by:

🔹 Tetrace. Specialized services in operation and maintenance, engineering, supervision, inspection, technical assistance, and distribution of spare parts in the wind sector. More information here.

🔹 RenerCycle. Development and commercialization of solutions and specialized services in the circular economy for renewable energies, including comprehensive dismantling of wind farms and waste management, refurbishment and sale of components and wind turbines, management and recycling of blades and others. More information here.

Windletter está disponible en español aquí

Most read from the latest edition: the wind turbine simulator video game, the video explaining the Gazelle Wind Power concept, and the analysis of offshore auctions in Europe by S&P Global.

Additionally, last week we published a special anniversary edition to celebrate 3 years and 100 news editions. We also launched a survey to gather your feedback and continue improving Windletter. If you haven't done it, you can do it here. It takes very little time and helps me a lot 🙂.

Now yes, let's go with the news of the week.

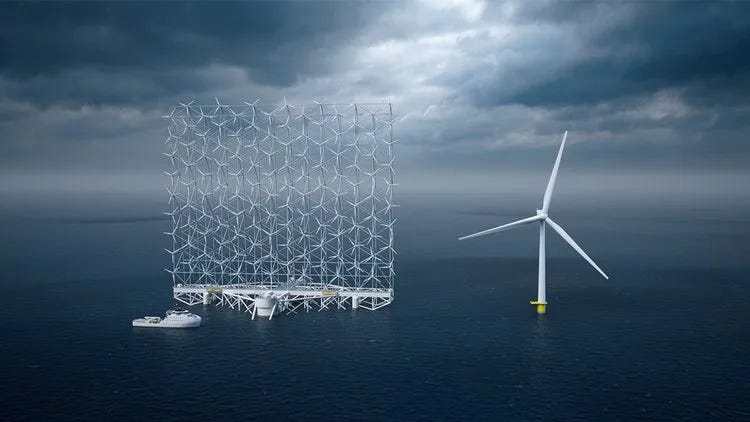

🌬️ Windcatcher, the world's first "wall" of turbines, secures funding for a prototype

The world's first "wall of turbines" could become a reality after Enova, an organization under Norway's Ministry of Climate and Environment, granted €102 million euros to the startup Wind Catching Systems for the construction of its first prototype.

The figures for this first prototype, scheduled for completion in 2029, are truly ambitious, featuring 40 "small" 1 MW wind turbines installed on a spectacular floating structure. It will be located northwest of Bergen, off Øygarden.

The funding comes after Wind Catching Systems won a competitive public funding tender. Interestingly, some more mature technologies did not receive funding, a decision that surprised Norwegian Offshore Wind (Norway’s offshore wind association).

The concept, which already has a preliminary analysis from DNV (Approval in Principle), proposes the following advantages over conventional wind power:

📌 Standardization: Small-sized wind turbines designed to be manufactured anywhere in the world with minimal investment. Additionally, avoiding turbine scaling allows for automation and innovation in manufacturing processes while promoting economies of scale.

📈 Scalability: The concept scales by increasing the structure's size, but the turbine technology and manufacturing process remain unchanged.

🌍 Efficient use of space: Electricity production per floating unit is maximized, optimizing the use of available area.

⚙️ Innovative O&M: The structure includes an "elevator" platform that allows access to and removal of each turbine without the need for large cranes or towing the platform to port. Additionally, stopping one or two turbines is not as critical for energy generation, and spare part availability is simplified.

On paper, the concept is very interesting, and the advantages it offers seem quite logical.

For those who want more details, it is highly recommended to listen to the interview by

with Ivar Knutsen, Senior VP of Technical and Supply Chain at Wind Catching Systems.In the quest to limit turbine scaling and optimize floating structures, the industry has seen several attempts to popularize dual-rotor platforms, such as Nezzy2 (now in full-scale version as OceanX by Mingyang), TwinWind, or even the Spanish company EnerOcean.

Meanwhile, in onshore wind, the most notable example is Vestas’ four-rotor multi-rotor prototype, which was tested for three years and showed some promising results.

However, the multi-rotor concept with dozens of rotors on a single platform has not yet been implemented under real operating conditions.

It is also worth mentioning that Wind Catching Systems (WCS) is not the only company proposing this type of multi-rotor design. Previously, in Windletter, we discussed Myriad Wind Energy Systems, a Scotland-based startup that is developing a similar concept (although currently focused on onshore applications). The company already holds a patent and has built a small prototype.

Looking further into multi-rotor wind turbines, we also find the Spanish research center CENER, which in 2023 introduced MUST, a specialized simulation software designed for analyzing these type of turbines.

Honestly, I’m very curious to see how this prototype progresses. However, it seems clear that if this truly turns out to be a technological disruption, it will be part of the next generation of offshore wind, likely within the 2030-2040 horizon.

Before making the leap to commercialization, Windcatcher needs to prove its reliability in real-world conditions, gain the trust of major developers, and become insurable and financeable in a market that is not particularly risk-tolerant.

What do you think? I encourage you to reply to this email or share your opinion in the comments section!

🌍 From Tahivilla (Cádiz, Spain) to Sri Lanka: the second life journey of a gearbox

While the industry and media often focus on the benefits of repowering in terms of reducing environmental impact and increasing energy generation, there are also some less visible advantages and secondary benefits.

A few months ago, in Windletter, we discussed the repowering project in Tahivilla (Cádiz), where ACCIONA Energía is replacing 98 MADE AE5X turbines with 13 Nordex N163/175 6.X units. We highlighted the spectacular 87% reduction in turbine positions and a 72% increase in energy production, all while maintaining a similar installed capacity.

But as we have mentioned, the benefits of repowering do not end there. This type of project forms the foundation for a flourishing circular economy of second-life turbines and components.

And that is precisely what our main sponsor, RenerCycle, is doing. They have published on LinkedIn the specific case of two gearboxes removed from Tahivilla.

Specifically, these are the PEAB 4300 model by Winergy, a piece of equipment manufactured in 2004 in Voerde (Germany) and installed in all MADE AE5X models. After being inspected and confirmed to be in good condition, these components have been sold to WindForce, a developer and operator in Sri Lanka.

Specifically, the second life of these two gearboxes will be in the Vidatamunai wind farm, located in Puttalam (Sri Lanka), which consists of 12 MADE AE59 units installed in 2010 (seven years after Gamesa acquired MADE). An 8,000 km journey to swap the winds of Tarifa for those of Sri Lanka and continue generating wind kWh for a few more years.

By the way, RenerCycle's new online store with second-life wind turbines and components is now available. And they already have some wind turbines for sale. You can take a look here.

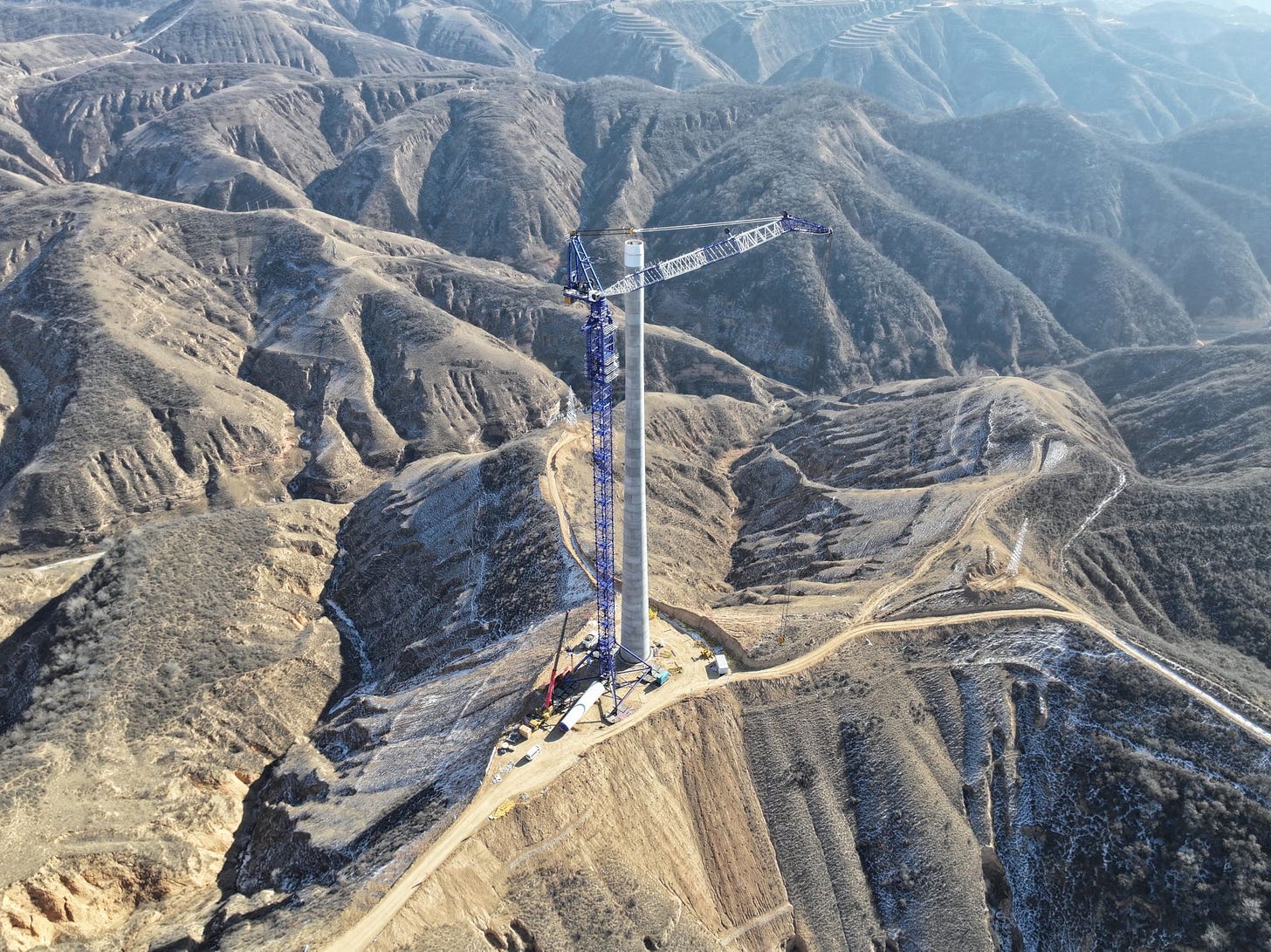

🏗️ The use of tower cranes in wind farms where there is barely any space for the platform

From the outside, assembling wind turbines may seem relatively simple: bring a crane and put together the different components as if it were a Lego set. However, the reality is that things can become much more complicated, especially when the terrain is not favorable.

The simplest assembly strategy is known as “full component storage.” This means that all turbine components are first stored on the assembly platform. Then, the crane arrives and assembles them (although sometimes this is done in phases).

The platform is also used for assembling the main crane, which, as you can see in the photo below, requires a lot of space for the boom.

However, there are other strategies that significantly reduce the platform size. This is especially useful in wind farms with complex terrain, where building large assembly platforms would require excessive civil works.

That is precisely what can be seen in the following photo I found on Bruce Li’s LinkedIn profile. As you can see, the wind turbine is located almost at the top of a mountain, where constructing platforms for full component staging would require disproportionate civil works. Moreover, a tower crane solution is used, which is assembled vertically, eliminating the need for space to mount the boom.

However, assembling this wind turbine with this platform leaves barely any space for component staging, which means a “just-in-time” strategy must be followed—assembling the components as they arrive. This usually results in higher transportation and crane costs. It’s all a matter of balance.

Disclaimer: I’m not an expert in cranes or assembly, so I invite you to correct any mistakes I may have made 🙂

🛠️ Manufacturing process of a 108-meter blade by DEC

Through the LinkedIn profile of Gang Wang, who frequently shares content about the Chinese wind sector, I came across the following video showcasing the manufacturing process of a 108-meter-long blade from the manufacturer Dongfang Electric Corporation (DEC).

According to Gang Wang, these blades are designed for 10 MW wind turbines and are the best-selling onshore models in China.

I have translated the video into English using an AI tool to make the content as understandable as possible.

As it can be seen, blade manufacturing still relies heavily on manual labor, as many processes are difficult to automate.

Moreover, the continuous growth in blade size significantly limits any attempt at automation. Since product cycles are so short, any investment in automation would also need to be compatible with the production of larger models.

For blade experts: do you see any differences compared to Western manufacturing?

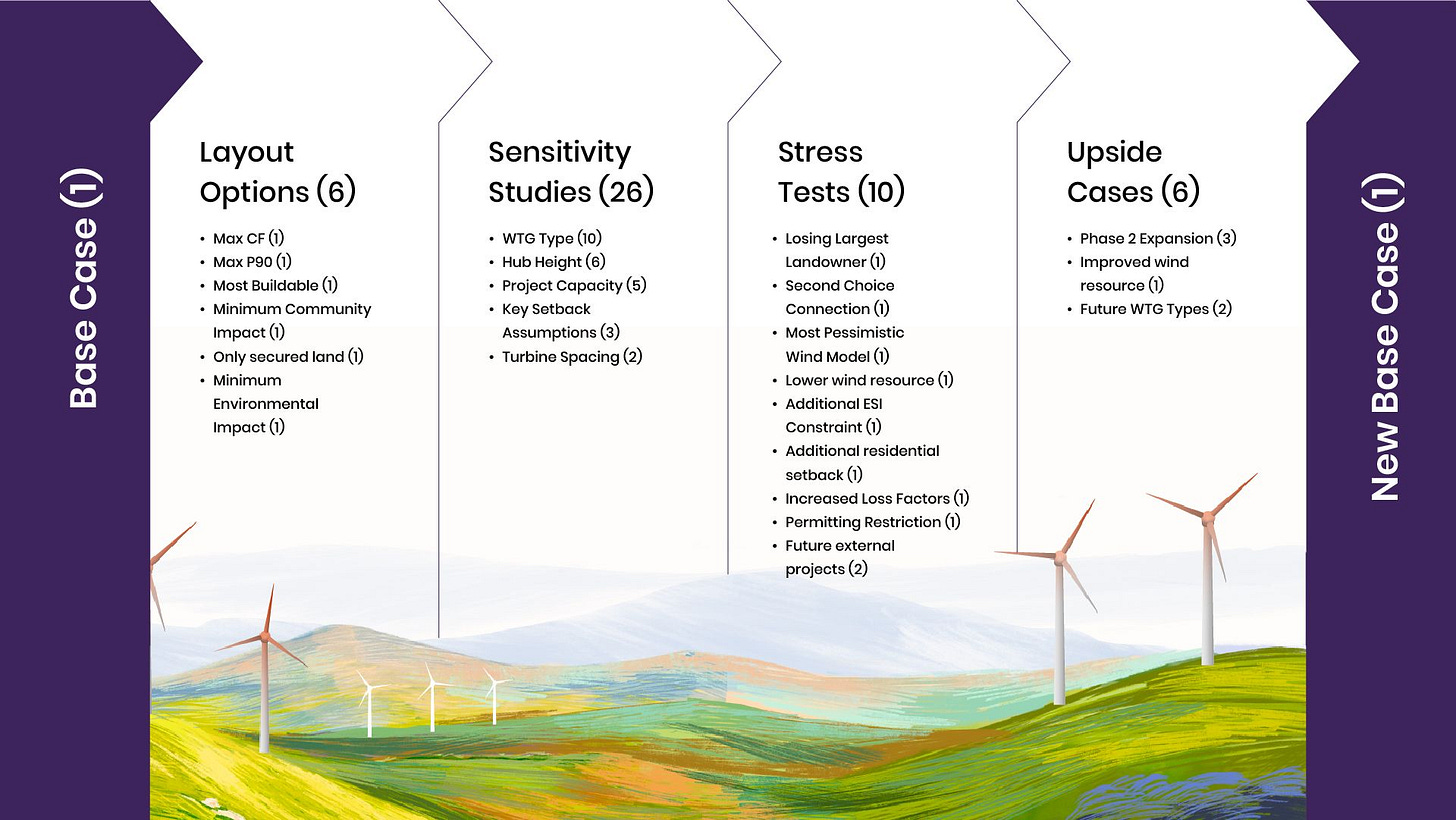

📊 Unlimited wind farm configurations for wind resource studies

I found this post by Jerry Randall, founder of Wind Pioneers, very interesting.

Jerry explains how, thanks to advances in software and automation, it is now possible to analyze multiple wind resource study scenarios for the same location. This was not feasible in the past when it was common to evaluate only three or four scenarios initially and charge extra for each additional case.

According to Jerry, after years of improving processes and efficiency, Wind Pioneers can now offer clients “all-you-can-eat” configurations. They provide an example in the table below, where 50 variables can be adjusted, each impacting the farm’s energy generation (as well as the initial investment), and therefore, the financial model and profitability.

In the different configurations, everything from the most basic aspects, such as the turbine model, to other parameters can be adjusted—such as increasing hub height, maximizing capacity factor, reducing environmental impact, or accounting for the effect of neighboring wind farms that may be built in the future.

In short, this approach allows for the analysis of numerous variables during a wind resource study, enabling better investment decisions.

🎨 Wind turbines with colored towers?

Here’s an interesting curiosity from Envision. I’ve often come across photos of wind farms (mainly in China) where turbines have towers painted in different colors. The ones recently shared by Envision on their LinkedIn account caught my attention.

The first example is in a forested area, where the towers are painted green and even feature leaf patterns, helping them blend better into the environment.

The second example is the complete opposite, with yellow and blue towers that make the wind turbines stand out from everything else.

These picturesque images are not commonly seen in other markets, where wind turbines are almost always white or gray (in the case of concrete towers), primarily guided by environmental impact studies.

A few months ago, we also mentioned in Windletter some wind turbines in Finland that had urban art paintings at the base of the tower.

What do you think?

Thank you very much for reading Windletter and many thanks to Tetrace and RenerCycle, our main sponsors, for making it possible. If you liked it:

Give it a ❤️

Share it on WhatsApp with this link

And if you feel like it, recommend Windletter to help me grow 🚀

See you next time!

Disclaimer: The opinions presented in Windletter are mine and do not necessarily reflect the views of my employer.