Windletter #114 - Innovation or Standardization?

Also: Nabrawind progresses on its first multi-turbine wind farm, a power cable that incorporates hydrogen transport, Vestas celebrates 30 years in offshore, and more.

Hello everyone and welcome to a new issue of Windletter. I'm Sergio Fernández Munguía (@Sergio_FerMun) and here we discuss the latest news in the wind power sector from a different perspective. If you're not subscribed to the newsletter, you can do so here.

Windletter is sponsored by:

🔹 Tetrace. Reference provider of O&M services, engineering, supervision, and spare parts in the renewable energy market. More information here.

🔹 RenerCycle. Development and commercialization of specialized circular economy solutions and services for renewable energies. More information here.

🔹 Nabrawind. Design, development, manufacturing, and commercialization of advanced wind technologies. More information here.

Windletter está disponible en español aquí

First of all, I wanted to thank you all. We have managed to become finalists of the 2025 El Periódico de la Energía Awards. And I say we, because without your support it wouldn't have been possible. This recognition is yours as well.

The other finalists are Alfredo García (Operador Nuclear), Joaquín Coronado, and Lars Hoffmann (Todos Eléctricos). They are all very good at what they do and have a huge following online.

This also shows me that, in the world of big internet numbers, quality matters more than quantity. Community matters more than audience.

Making it to the final is much more than I expected, so thank you all very much 🙂

The most-read topics in the latest edition were: Lazard’s report on LCOE, the video of the installation of anchors for floating systems, and the life cycle analysis of the SG 5.0-145 (2.0).

Now, let’s get to this week’s news.

🧠 Innovation or Standardization: ¿what does the wind power sector need?

Innovation has been the driving force that has brought offshore wind to its current level of maturity. Innovation which, combined with competition, has been key for wind power in general, and offshore in particular, to become the industry it is today.

This development has taken place in barely 30 years, during which turbines have grown non-stop in size and power. Particularly over the past 10–15 years, the pace has been dizzying and probably excessive.

But the European sector now faces a strategic crossroads: is it better to keep scaling up turbine size to 20+ MW, or should we consolidate and standardize the existing technology?

This is precisely the debate that, once again, RWE has brought to the table through the LinkedIn account of its Offshore CEO, Sven Utermöhlen. I think I’ve said this here several times already, but hats off to RWE’s communication policy, always spreading knowledge about the sector and bringing important discussions to the table.

The mere fact that it is RWE pushing this conversation (even though Vestas has touched on it many times) already says a lot. Because RWE is a project developer, not a turbine manufacturer. But it’s also one of the main clients of Vestas and SGRE, so its influence is surely key in determining where future developments and innovations go.

Moreover, it is very relevant to note that during offshore construction, the involvement and collaboration between project developers and OEMs is much closer than in onshore, where the OEM is limited to manufacturing, transporting, installing, and commissioning.

In this case, I believe it's the first time a developer has publicly stated that “betting on ever-larger turbines is not necessarily the best answer right now.”

“Is it really wise to build ever-larger turbines —perhaps models over 20 MW— at this time? Or should we standardize what we already have? My opinion is clear: we must not stop innovating, but larger turbines are not the solution for now, and are not yet ready for widespread use. Their adoption is only justified if the increase in size and cost is sufficiently offset by substantial gains in revenue. Especially in difficult times for planning and developing offshore wind farms, the goal must be to offer developers the most attractive business cases for investment, as only the most valuable projects will be realized.”

Utermöhlen also mentions that it’s not just about the wind turbine:

“Additionally, the supply chain must be ready: installation tools, vessels, port capacities, and infrastructure for these heavier turbines must be developed in parallel. Investments must be made, and to get a return on those, a certain number of turbines must be installed. Right now, we haven’t even fully entered the industrialization phase for the largest turbines currently available, the 15 MW class. When a new turbine type is used for each project, everything becomes a prototype —with its benefits, but also all its risks."

I wonder if this is also some kind of message to the OEMs, especially SGRE and Vestas (since for now, GE, with its Haliade X issues, is neither present nor expected).

On one hand, we have SGRE, which has developed the SG21.5-276 DD (known as MkVII), but which has not yet been released for sale. It’s very likely that this turbine has already been offered or at least “shown” to developers so they could start doing the math and fitting it into their projects. But it’s also very likely that since it was first presented, SGRE’s plans have changed a lot.

SGRE has faced financial problems, management changes, and a lower risk appetite, while project CAPEX and turbine prices have increased significantly (as Ørsted points out in its white paper)… all of this has led the manufacturer to put this turbine “on hold” for now. And very likely RWE with some unviable business cases as well.

On the other hand, we have Vestas, who has publicly advocated several times for slowing down the development of larger turbines. Their bet on industrializing the V236-15.0 MW seems clear.

Have we reached the point where increasing size and power is no longer the best option for the business case? Can the costs of 15 MW turbines be reduced by innovating in industrialization and optimizing current designs?

Seems to be the bet and what we are going to see mainly in the next decade.

Meanwhile, in China, they’re doing their own thing: developing increasingly larger turbines and accumulating operational experience while keeping an eye on Europe, with Mingyang as the spearhead.

And you, what’s your take on this?

🏗️ Nabrawind moves forward with its first multi-turbine wind farm in Namibia

Our sponsor Nabrawind is making solid progress on the first phase of the InnoVentDíaz wind farm. Located in Namibia, south of the city of Lüderitz and developed by InnoVent, it is the second wind farm in the African country.

InnoVent is a French developer that, true to its name, uses innovative solutions in many of its projects. So much so that Nabrawind has become a regular supplier for them.

In the case of the InnoVentDíaz wind farm, the scope of the Navarre-based company includes:

Design of four Nabrabase foundations.

Design, manufacturing, and complete assembly of four towers (including both the transition piece and the tubular section).

InnoVent has published on its LinkedIn account an image of the assembly work of the tripod-style transition piece that serves as the interface between the foundation and the tubular tower.

This project marks several milestones for Nabrawind:

First wind farm with a multi-turbine scope. Until now, contracts had been limited to single-unit projects.

Fourth distinct Nabrabase foundation typology after: Gravity-based (Eslava), Monopile (Oualidia), Multi-pile (Le Portel), and Rock-anchored (InnoVentDíaz I). You can find more information on the different Nabrabase foundation typologies here.

Its multi-country industrial capacity is confirmed, with active manufacturing in Spain and China.

As you can see in the images below, the first units of the wind farm are already installed. You have more pictures here.

Nabrawind also tells us they are already working on all continents, although they cannot yet announce specific countries and projects.

We will continue to follow their developments closely.

🧱 The innovative airBASE foundations by HWS Towers

HWS Towers, a company based in San Sebastián specializing in structural solutions for wind turbines, has announced that its innovative AirBASE foundation design has received a new certification from TÜV SÜD.

This certification supports the conceptual and structural design of the foundation for a specific wind farm with 8 MW turbines, consolidating its technical validity for real-world implementation.

One of the key features of this version of AirBASE is the complete prefabrication of components, which facilitates the industrialization of the process and significantly reduces on-site timelines and risks.

According to HWS, this configuration allows savings of up to 45% in concrete volume and 40% in steel, in addition to a 50% reduction in on-site labor hours. In return, of course, it requires greater logistical effort (from the precast concrete factory to the wind farm) and proper supervision during the assembly of components.

More information about the solution can be found in the following poster (pdf):

According to HWS, construction is expected to begin in the coming months on a pilot project that will include at least 3 wind turbines. For now, the country or client is unknown, but the fact that the turbines will be 8 MW gives us a clue that it may be in a market with a presence of Chinese OEMs.

Those interested in learning about onshore wind turbine foundations can read the following article.

⚡ A 66 kv power cable that incorporates hydrogen transport pipes

A 66 kV submarine cable that also transports hydrogen? I was struck by the following photo I found on LinkedIn, where you can see a 66 kV three-core submarine cable that incorporates two copper tubes for H₂ transport integrated alongside the electrical conductors.

Developed by the Greek manufacturer Hellenic Cables, they have designed, manufactured, and tested this hybrid cable for the Offshore Energy Hubs project. In the post, they refer to it as an “umbilical cable.”

The cable, type 3x800 RM 38/66 kV, represents a new paradigm in offshore infrastructure: with a single laying and a single connection, both electricity and hydrogen could be transported. This could be applied in future offshore wind farms capable of both exporting electricity to the grid and generating hydrogen on site.

As usual, these types of hybrid solutions help reduce the cost of installing separate infrastructures at the expense of increased cable complexity and more severe consequences in the event of failure.

🌬️ Video of the SG21.5-276 from Siemens Gamesa generating at 9 m/s

Photographer Klaus Rockenbauer has shared on his Instagram account a beautiful video where you can see the SG21.5-276 prototype spinning in Østerild with a wind speed of 9 m/s, probably very close to nominal speed.

We recently commented in Windletter on some of the new features of this model, which remains unavailable commercially, and according to public statements from SGRE, it is unknown when it will be.

If you enjoy wind energy photos and videos (I personally love them), I highly recommend following Klaus Rockenbauer both on Instagram and on his website www.global-windphotos.com, where he publishes truly spectacular images.

You can read the latest updates we've shared on the SG21.5-276 here.

🌊 Vestas celebrates 30 years in offshore: remembering the Tunø Knob wind farm

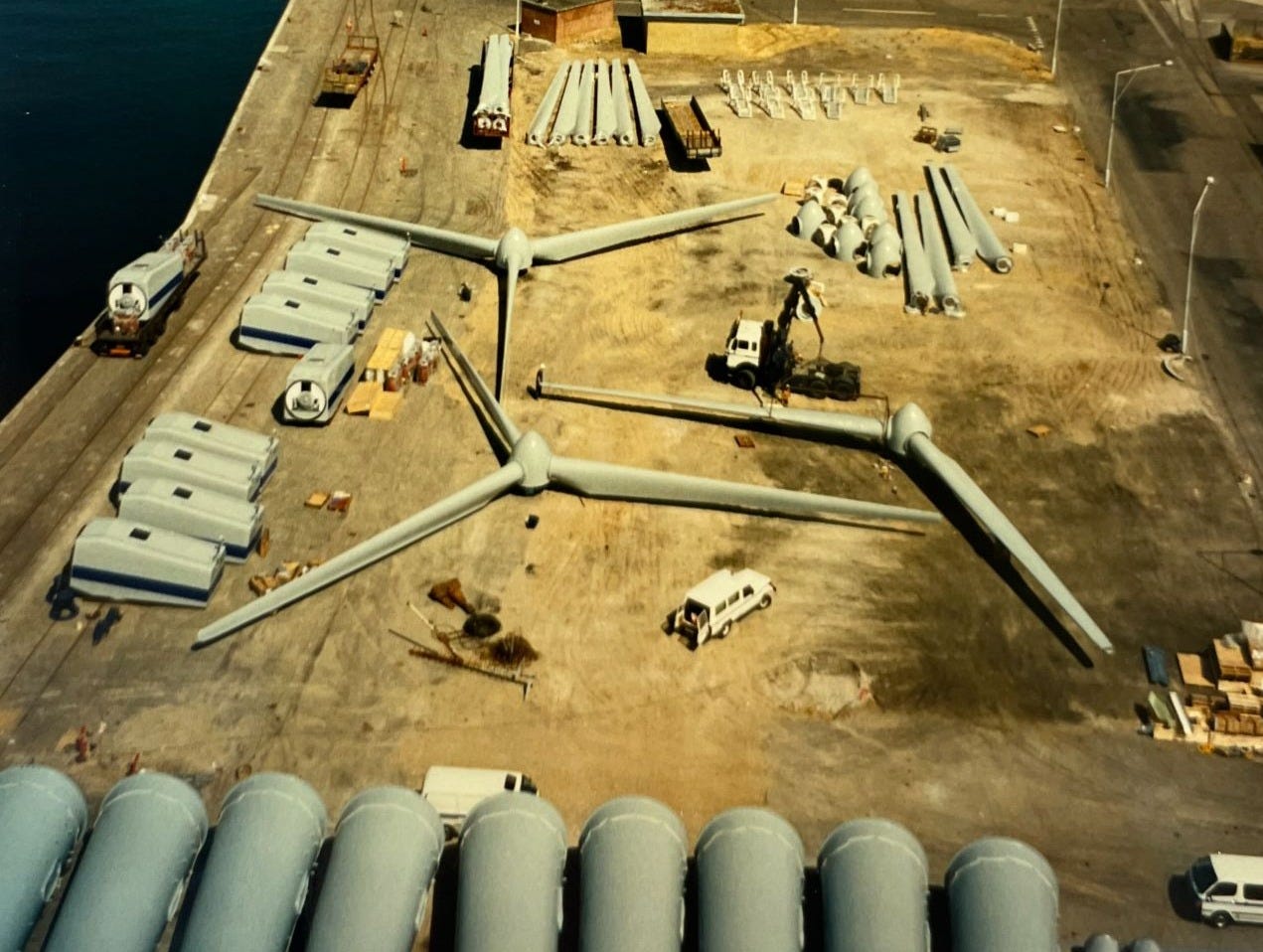

The Danish wind giant celebrates 30 years in offshore. It has already been three decades since Vestas completed the installation of Tunø Knob in 1995, the first offshore wind farm in its history (link to Maps).

The park, which is still operational today, consists of 10 V39 turbines of 500 kW installed on the Danish coast, next to the island of Tunø, in the Kattegat strait. It was both a technical and symbolic milestone, marking the beginning of an industry that is now global.

As it couldn’t be otherwise for the story to fit perfectly, the park is owned by Ørsted (then known as DONG Energy), Denmark's leading energy company and a global leader in offshore wind.

As a curious fact, and as can be seen in the photo below, the turbines were installed on concrete foundations in waters just 3 to 6 meters deep, which enabled a simple and cost-effective structural solution for that time.

According to Vestas on LinkedIn, the installation director at the time, Bjarne Iversen, as well as two members of his team (Peer Jessen and Mogens E), are still with the company 30 years later: “It was the first time we were installing turbines at sea, and everything was new,” Bjarne recalls. “But we got it right the first time, ahead of schedule and under budget.”

That small wind farm paved the way for a Vestas that today has 1,500 offshore turbines installed worldwide and a pipeline of over 14 GW for its V236-15.0 MW.

We also recently celebrated that Siemens Gamesa had installed its 5,000th offshore turbine.

Thank you very much for reading Windletter and many thanks to Tetrace, RenerCycle and Nabrawind our main sponsors, for making it possible. If you liked it:

Give it a ❤️

Share it on WhatsApp with this link

And if you feel like it, recommend Windletter to help me grow 🚀

See you next time!

Disclaimer: The opinions presented in Windletter are mine and do not necessarily reflect the views of my employer.